Metal Recycling and Separation Equipment

Over band magnets (self cleaning magnets)

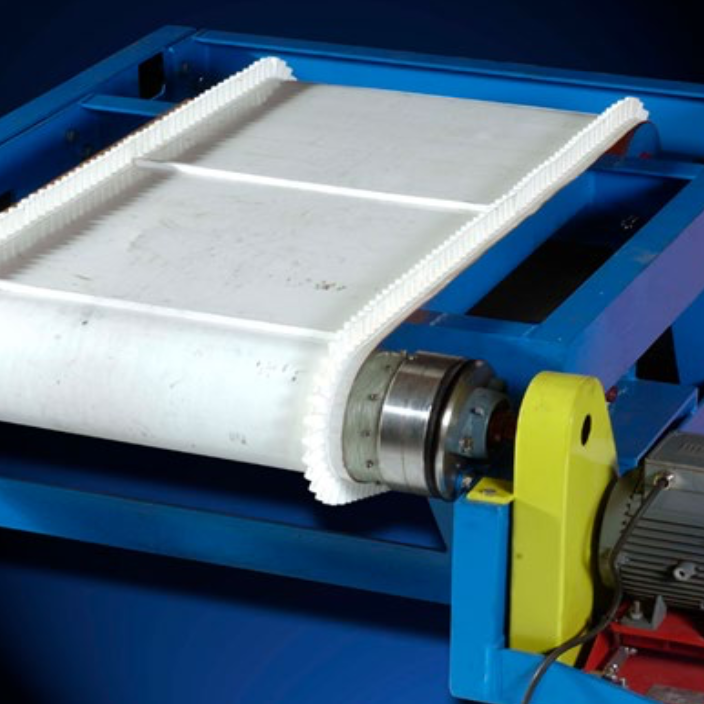

Overband Magnet Conveyor – Description

An overband magnet conveyor, also known as an overband magnetic separator, is a type of conveyor system that incorporates a powerful magnet positioned above a conveyor belt. Its primary function is to automatically extract and remove ferrous metals (such as iron and steel) from bulk materials being transported along the conveyor.

The overband magnet is typically suspended above the conveyor and uses a continuously rotating belt that sweeps captured metal contaminants away from the product stream into a separate collection area. These systems are commonly used in recycling, mining, quarrying, and material handling industries to enhance product purity and protect downstream equipment from damage caused by metal contamination.

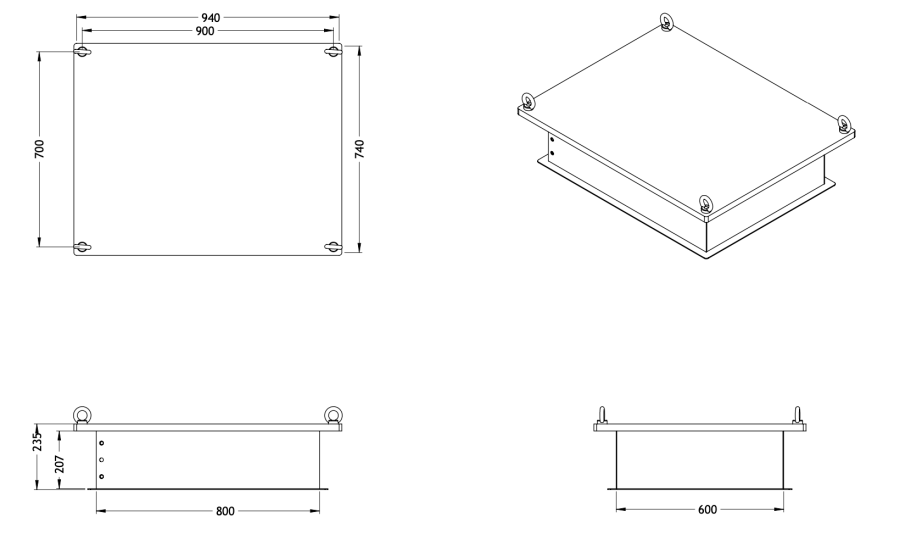

Block magnets (suspended magnet)

Overview

A suspended block magnet (also known as a suspension magnet) is a rectangular, permanent or electromagnet designed to hang over a conveyor belt or vibratory feeder. Its primary function is to attract and remove iron-containing contaminants from the conveyed materials, thereby protecting downstream equipment like crushers, grinders, or screens and ensuring product purity.

ECS (Eddy Current Separator)

Working Principle

It operates on the principle of electromagnetic induction. Here's how it works:

Rotating Magnetic Drum: A high-speed rotor with powerful permanent magnets rotates inside a non-metallic drum at one end of a conveyor belt.

Eddy Currents: As mixed materials travel across the conveyor, non-ferrous metals passing through the magnetic field experience rapidly changing magnetic fields, which induce eddy currents in them.

Repulsive Force: These currents create opposing magnetic fields in the metals, generating a repelling force that ejects them away from the rest of the material stream.

Separation: Non-metallics (like plastics or glass) and ferrous metals fall straight down off the end of the belt, while non-ferrous metals are flung forward into a separate collection area.